Advanced Techniques in Pipeline Welding Assessment: Technologies and Technologies for Enhanced Accuracy and Integrity in Weld Assessment

The landscape of pipe welding inspection is undertaking a substantial makeover, driven by sophisticated techniques that assure to improve both precision and dependability in weld analyses. Advancements such as automated inspection systems and progressed imaging technologies are redefining traditional methods, while non-destructive testing methods ensure material integrity is kept. As these technologies develop, they not just elevate defect discovery prices however likewise make it possible for extra efficient upkeep approaches. However, the effects of these developments prolong beyond prompt benefits, raising critical questions concerning future techniques and standards in the sector.

Value of Weld Evaluation

Guaranteeing the stability of pipe welds is essential to the overall safety and integrity of industrial systems. Rigorous examination of welds is indispensable to the lifecycle of pipe framework.

The significance of weld examination prolongs past simple conformity with regulative criteria. It functions as an aggressive step to determine and correct blemishes, such as incomplete blend, porosity, or cracks, prior to they escalate into significant issues. Efficient examination methods also contribute to the longevity of pipelines, reducing upkeep costs and enhancing functional efficiency.

Furthermore, extensive weld inspections foster trust amongst stakeholders, consisting of governing bodies, capitalists, and the areas offered by these pipes. By ensuring that all welds satisfy the needed requirements, organizations can alleviate dangers and copyright their credibilities. In summary, weld assessment is important not only for functional honesty yet also for the more comprehensive effects it holds for security and environmental stewardship.

Automated Assessment Solutions

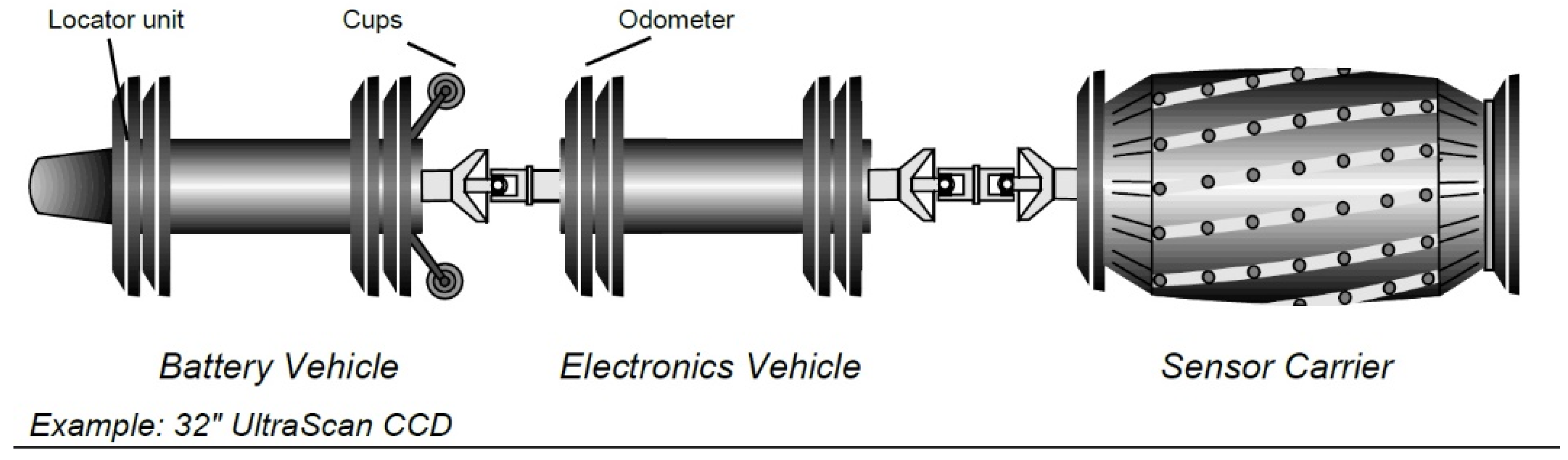

The integration of automatic assessment systems in pipeline welding has reinvented the method to making certain weld top quality and stability. These systems employ advanced robotics and expert system to conduct evaluations that are not just faster yet additionally a lot more consistent than standard methods. Automated systems can cover comprehensive sizes of pipes effectively, catching information that human examiners could forget as a result of exhaustion or ecological conditions.

Among the key benefits of automatic assessment systems is their capacity to operate in harmful environments, minimizing the danger to human inspectors. They use different non-destructive screening (NDT) strategies, such as ultrasonic screening and magnetic bit examination, to analyze weld honesty without endangering the structure. The information gathered is processed in real-time, allowing for immediate comments and prompt corrective activities when issues are determined.

In addition, automated systems promote the standardization of inspection processes, making sure that each weld is examined versus consistent requirements. This not only enhances the dependability of results but additionally improves compliance with regulative criteria. As markets continue to prioritize safety and operational performance, the duty of computerized assessment systems in pipe welding will unquestionably expand, leading the way for a lot more advanced quality control techniques.

Advanced Imaging Technologies

Regularly employed in contemporary pipe welding examinations, advanced imaging innovations have actually substantially improved the ability to spot and assess weld problems. Techniques such as digital radiography, computed tomography, and thermographic imaging supply inspectors with high-resolution photos that disclose sub-surface defects and structural disparities that might be unnoticeable to the naked eye.

This leads to quicker examinations and improved accuracy in determining critical problems. Computed tomography, on the various other hand, uses three-dimensional imaging, making it possible for inspectors to picture complex geometries and assess the stability of welds from numerous angles.

Thermographic imaging utilizes infrared innovation to detect variants in temperature, recognizing areas of prospective weakness or stress and anxiety within the weld. These sophisticated imaging modern technologies not just boost flaw discovery rates yet additionally minimize the time and resources needed for pipeline examinations. As a result, they play a vital function in maintaining pipe safety and reliability, ensuring compliance with market requirements while reducing functional threats.

Non-Destructive Evaluating Approaches

Making use of numerous strategies, non-destructive screening (NDT) methods are vital in pipeline welding assessments, allowing for the analysis of weld honesty without compromising the material's structural honesty. NDT incorporates a variety of methods, consisting of ultrasonic testing (UT), radiographic screening (RT), magnetic particle screening (MT), and dye penetrant screening (PT) Each approach has distinctive advantages and applications depending upon the details demands of the inspection.

Ultrasonic testing utilizes high-frequency sound waves to find inner flaws, supplying specific measurements of weld density and stability. Pipeline Welding Inspection. Radiographic testing uses X-rays check my site or gamma rays to produce photos of the weld, exposing internal issues that may not show up externally. Magnetic particle screening works for finding surface area and near-surface stoppages in ferromagnetic materials, while dye penetrant testing highlights surface area splits by utilizing a tinted dye

Including these NDT methods right into pipeline welding assessments enhances the precision and have a peek here reliability of weld analyses, ensuring that prospective failings are determined early. As industries demand greater requirements for safety and efficiency, the function of NDT in keeping the stability of bonded structures proceeds to be essential in pipe building and upkeep.

Future Patterns in Weld Evaluation

As we look to the future of weld assessment, improvements in technology are poised to revolutionize the approaches utilized for assessing pipeline honesty. The assimilation of expert system (AI) and maker knowing in inspection procedures is expected to improve the precision of problem detection and anticipating maintenance. These modern technologies enable for real-time data analysis, making it possible for inspectors to determine prospective issues prior to they intensify right into considerable issues.

Additionally, using drones equipped with innovative imaging systems is acquiring traction. These airborne examinations can cover huge locations swiftly, catching high-resolution pictures and information that can be assessed for problems in hard-to-reach places. This not just improves safety and security however also enhances performance in the assessment procedure.

Additionally, the development of wise sensing units installed in pipe systems supplies the possibility for constant surveillance. These sensing units can identify changes in stress, temperature level, and resonances, providing important understandings right into the health of the welds over time.

Final Thought

Finally, the integration of sophisticated techniques in pipe welding evaluation significantly boosts the accuracy and integrity of weld assessments. Technologies such as automated assessment systems, advanced imaging modern technologies, and non-destructive testing techniques play a crucial role in boosting defect detection prices and fostering positive maintenance strategies. As these modern technologies remain to evolve, they will better his comment is here guarantee the security and performance of pipeline systems, inevitably adding to the integrity of critical facilities.